Galvanisation

At IRA Metal, we provide in-house hot-dip galvanisation services to ensure rust-free protection for all our fabricated steel products. This zinc coating process protects steel from environmental wear, significantly extending the life of outdoor infrastructure. With both 7-meter and 1.5-meter galvanizing baths, we serve custom and bulk orders with precision.

Key Benefits

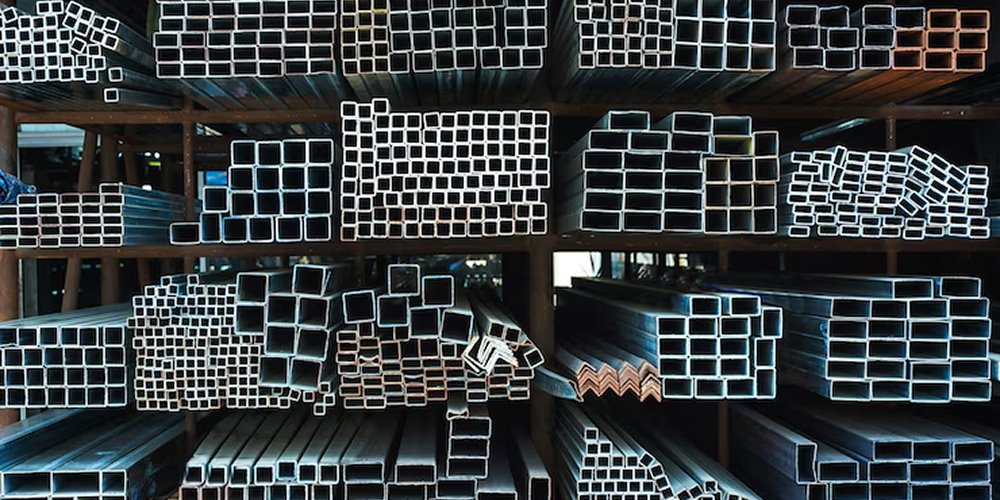

- Uniform coating for all types of steel sections

- Enhances longevity by 25+ years

- Prevents corrosion even in coastal/humid areas

- IS/ASTM standard-compliant

- Fast turnaround for in-house and external jobs

Applications

- Solar structures, poles, and towers

- Transmission and telecom steel

- Street lighting and fencing products

- OEM and project-specific components

Work Process

Our commercial solar solutions help businesses save on energy costs and reduce carbon footprints. We handle complex, large-scale installations tailored to each company’s unique energy needs, helping businesses become more sustainable and energy-efficient. Solar inverters convert the DC electricity generated by solar panels into AC power that’s usable in your home or business.

Design & Engineering

We begin by understanding your specific project requirements and site conditions. Our engineering team then prepares detailed drawings, structural calculations, and material specifications tailored to your use case — ensuring compliance, safety, and cost-efficiency.

Fabrication & Galvanization

Once the design is approved, we move to precision fabrication at our fully-equipped facility. Every component is cut, welded, and shaped using advanced CNC and roll-forming machinery — followed by hot-dip galvanization for long-term corrosion resistance and durability.

Delivery & On-Site Installation

All components are securely packed and dispatched to your site. Our expert installation team or your contractors can then assemble the structure with ease, supported by detailed drawings and technical guidance from our project team.